In the field of wastewater treatment, both polyaluminum chloride (PAC) and aluminum sulfate are widely used as coagulants. There are differences in the chemical structure of these two agents, resulting in their respective performance and application. In recent years, PAC has been gradually favored for its high treatment efficiency and speed. In this article, we will discuss the differences between PAC and aluminum sulfate in wastewater treatment to help you make a more informed choice.

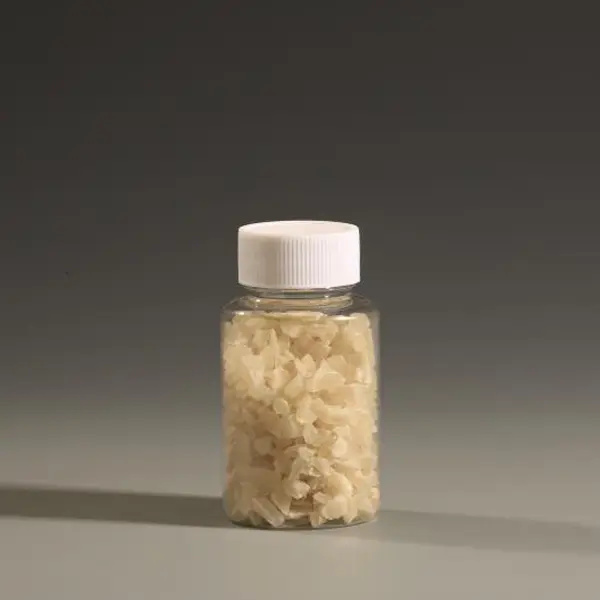

Firstly, let’s learn about polyaluminum chloride (PAC). As an inorganic polymer coagulant, PAC has excellent solubility and can quickly form flocs. It plays a coagulation role through electric neutralization and net trapping, and is used in conjunction with flocculant PAM to effectively remove impurities in wastewater. Compared with aluminum sulfate, PAC has stronger processing ability and better water quality after purification. Meanwhile, the cost of water purification of PAC is 15%-30% lower than aluminum sulfate. In terms of consuming alkalinity in water, PAC has lower consumption and can reduce or cancel the injection of alkaline agent.

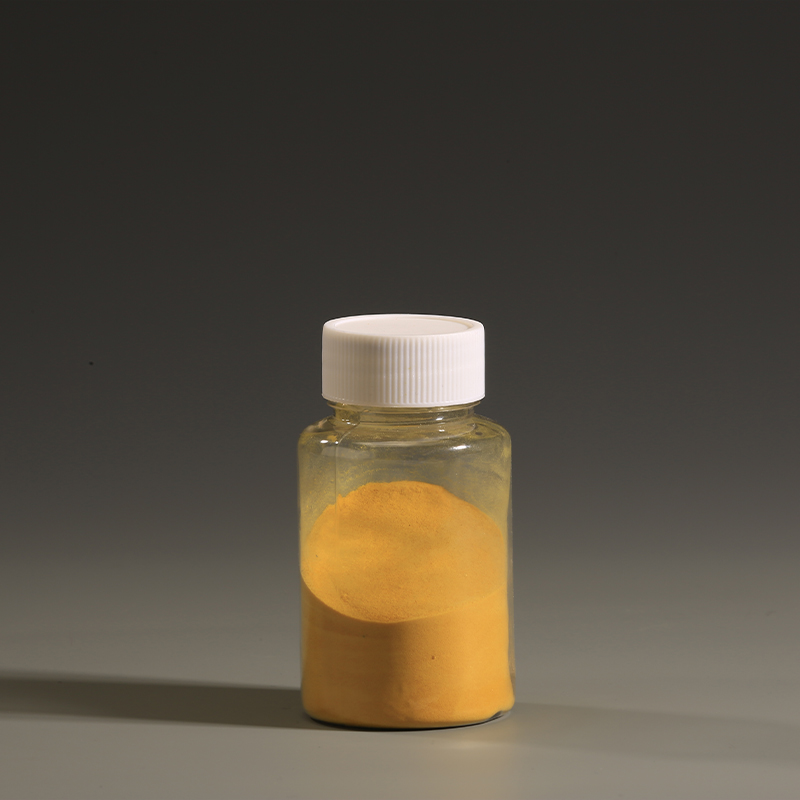

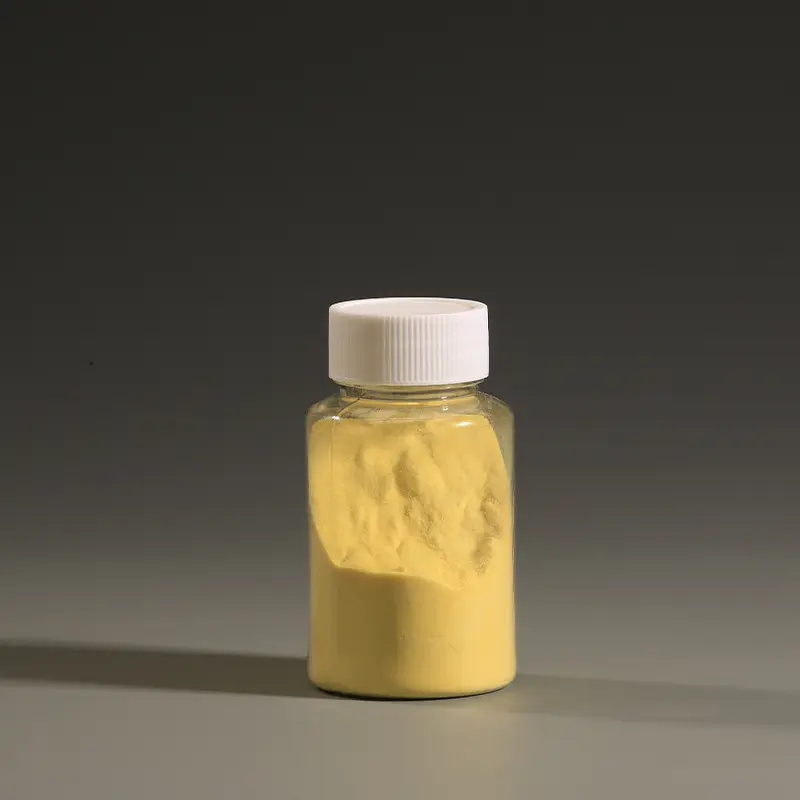

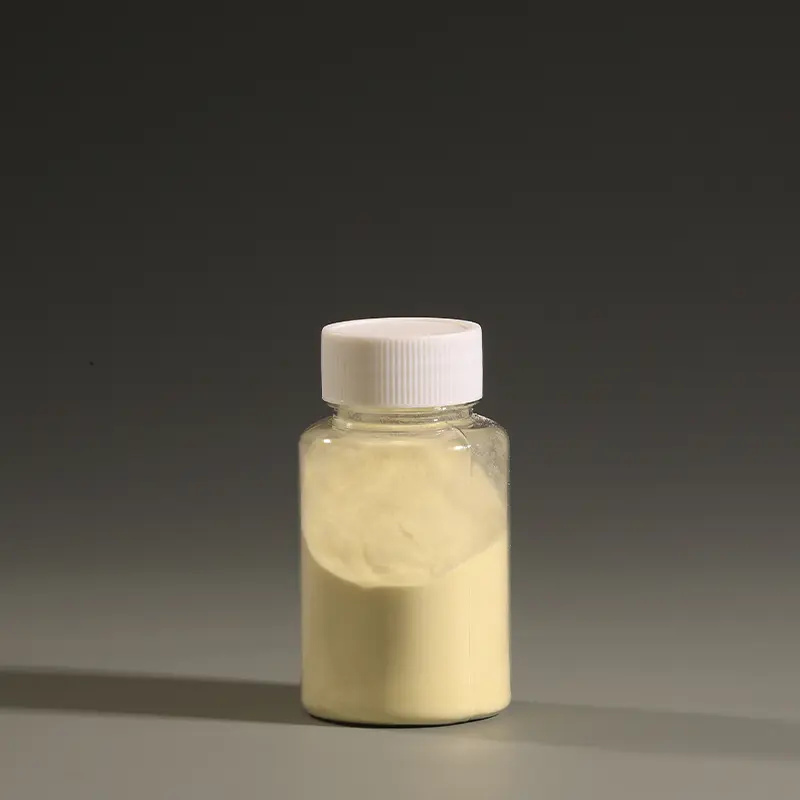

Next is aluminum sulfate. As a traditional coagulant, aluminum sulfate adsorbs and coagulates pollutants through aluminum hydroxide colloids produced by hydrolysis. Its dissolving rate is relatively poor, but it is suitable for wastewater treatment with a pH of 6.0-7.5. Compared with PAC, aluminum sulfate has inferior treatment capacity and purified water quality, and the cost of water purification is relatively high.

In terms of operational dimensions, PAC and aluminum sulfate have slightly different applications; PAC is generally easy to handle and forms flocs quickly, which improves treatment efficiency. Aluminum sulfate, on the other hand, is slow to hydrolyze and may take longer to coagulate.

Aluminium sulfate will decrease the pH and alkanility of treated water, so soda or lime is needed to neutralize the effect. PAC solution is close to neutral and no requirement for any neutralising agent (soda or lime).

In terms of storage, PAC and aluminium sulfate are usually stable and easy to store and transport. While PAC should be sealed to prevent moisture absorption and exposure to sunlight.

In addition, from the point of view of corrosivity, aluminum sulfate is easy to use but more corrosive. When choosing coagulants, the potential impact of both on the treatment equipment should be fully considered.

In summary, Polyaluminum Chloride (PAC) and aluminum sulfate have their own advantages and disadvantages in sewage treatment. Overall, PAC is gradually becoming the mainstream coagulant due to its high efficiency, rapid wastewater treatment capability and wider pH adaptability. However, aluminum sulfate still has irreplaceable advantages under certain circumstances. Therefore, when choosing a coagulant, factors such as actual demand, treatment effect and cost should be considered. Choosing the right coagulant will help improve the efficiency of wastewater treatment.

Post time: Oct-29-2024