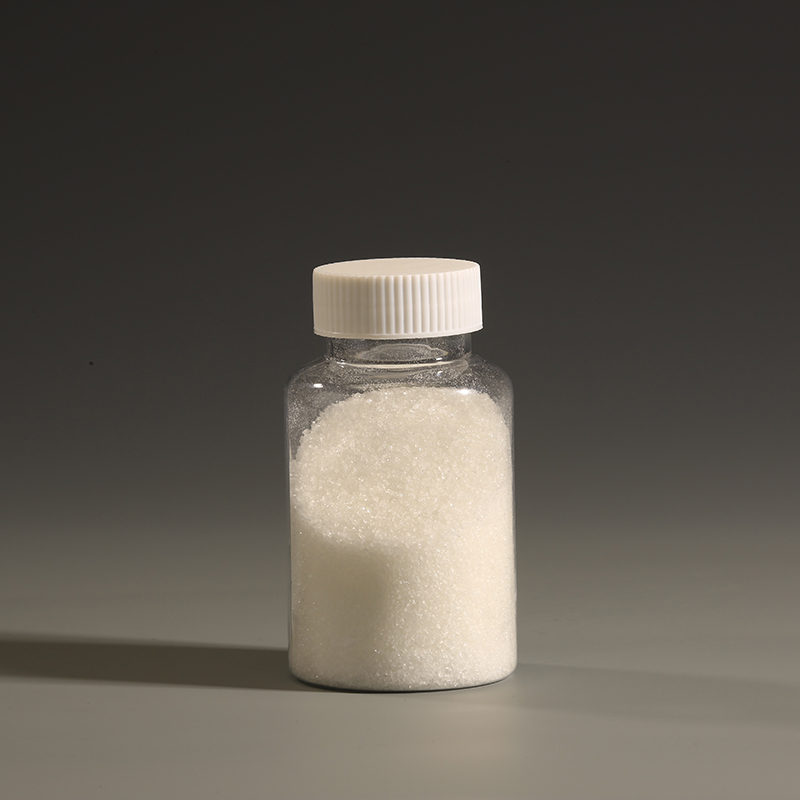

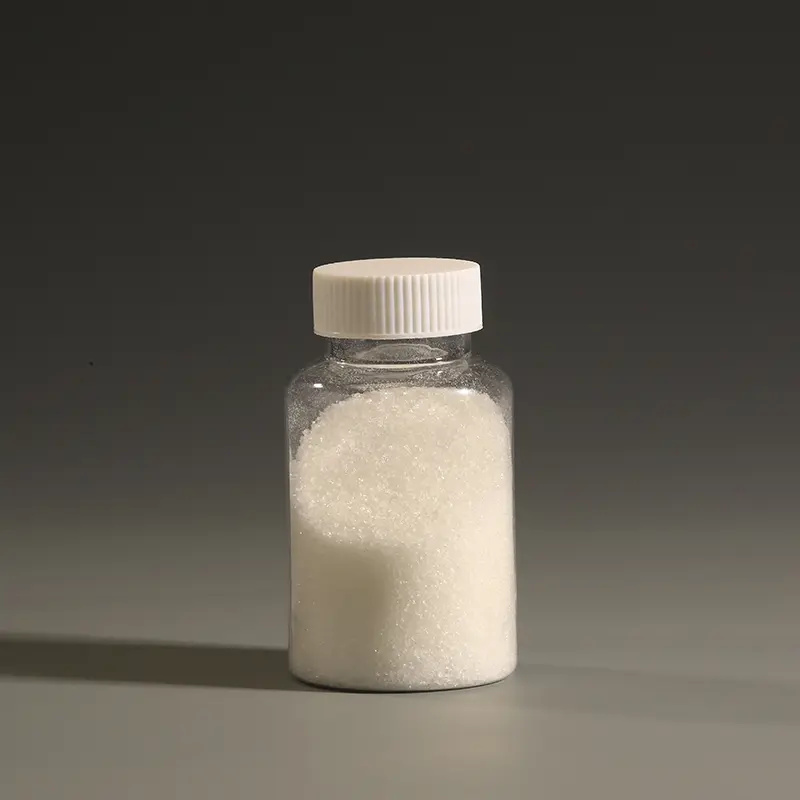

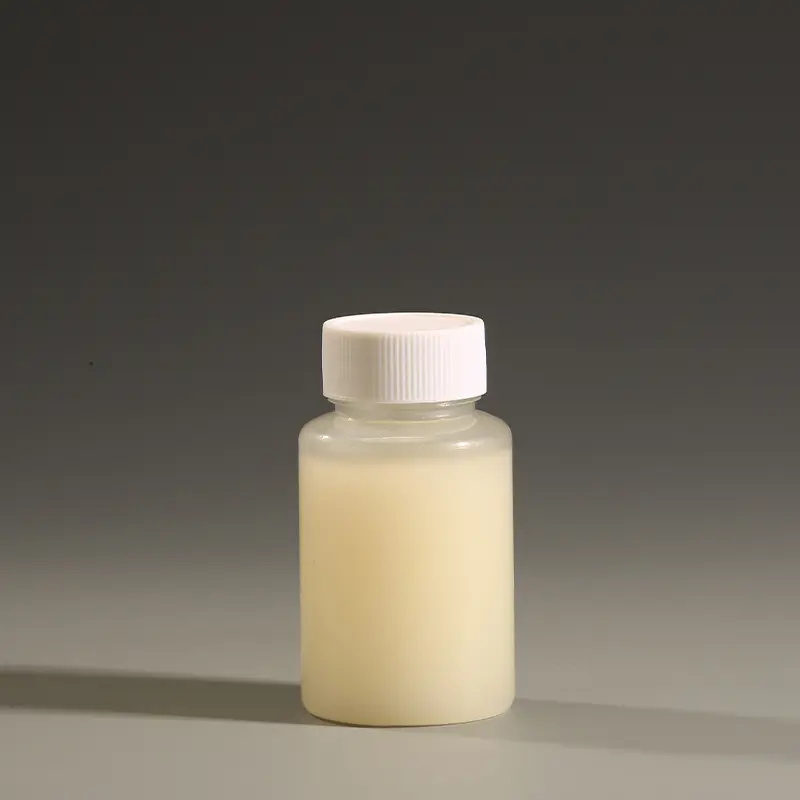

Polyacrylamide is a general term for homopolymers of acrylamide or copolymers with other monomers. It is one of the most widely used water-soluble polymers. Polyacrylamide exists in the form of white granules and can be classified into four types: non-ionic, anionic, cationic, and amphoteric ionic.

Applications of Polyacrylamide in the Papermaking Field

The papermaking process consists of several stages, including pulping, screening, cleaning, refining, and forming. During these processes, various impurities such as fibers, fillers, and fines are generated. If these impurities are not properly removed from the pulp, they can lead to problems such as poor drainage and low paper strength. Polyacrylamide is mainly used as dispersant, retention aid, drainage aid, flocculant, and sizing agent in papermaking process.

Ⅰ. Dispersant

Adding a polyacrylamide dispersant during the papermaking process can effectively prevent the agglomeration of fibers and improve the uniformity of the paper. A low addition amount can promote the good dispersion of papermaking fibers and achieve an excellent paper-forming effect. It can also improve the pulp uniformity and the softness of the paper, and enhance the strength properties of the paper. It is suitable for various household paper products such as toilet paper, napkins, facial tissues, and other thin papers. In some paper mills, it can completely replace Polyethylene Oxide (PEO).

Ⅱ. Retention Aid

PAM is commonly used as a retention aid in the papermaking industry to increase the fiber retention rate and reduce sewage discharge. Its working principle is to form large flocs with small particles, which can be easily removed from the pulp through filtration or sedimentation.

Ⅲ. Drainage Aid

PAM can also serve as a drainage aid in the papermaking process. It increases the drainage rate, enabling faster and more efficient dewatering of the paper on the paper machine. This helps to increase the production speed and reduce energy consumption by shortening the drying time required for the paper.

Ⅳ. Sizing Agent

In some cases, polyacrylamide is used as a sizing agent in papermaking to control the penetration of water and other liquids into the paper sheet. This helps in achieving desired properties such as water resistance and ink holdout, particularly in applications where the paper needs to withstand moisture or printing processes.

Ⅴ. Flocculant

During the wastewater treatment process in paper mills, polyacrylamide can be used as a flocculant to remove suspended solids and pollutants in the wastewater. It helps to form larger particles called flocs, which can then be easily removed through the sedimentation or filtration process. This contributes to reducing water pollution and improving the environmental sustainability of the papermaking business.

Overall, the versatile properties of polyacrylamide make it an indispensable additive in the papermaking industry, contributing to improved efficiency, product quality, and performance of paper products. The application of polyacrylamide in the papermaking field spans the entire papermaking industry chain, from paper production to wastewater treatment. It not only improves the quality and production efficiency of paper, reduces production costs, but also makes a positive contribution to environmental protection.

Post time: Mar-21-2025