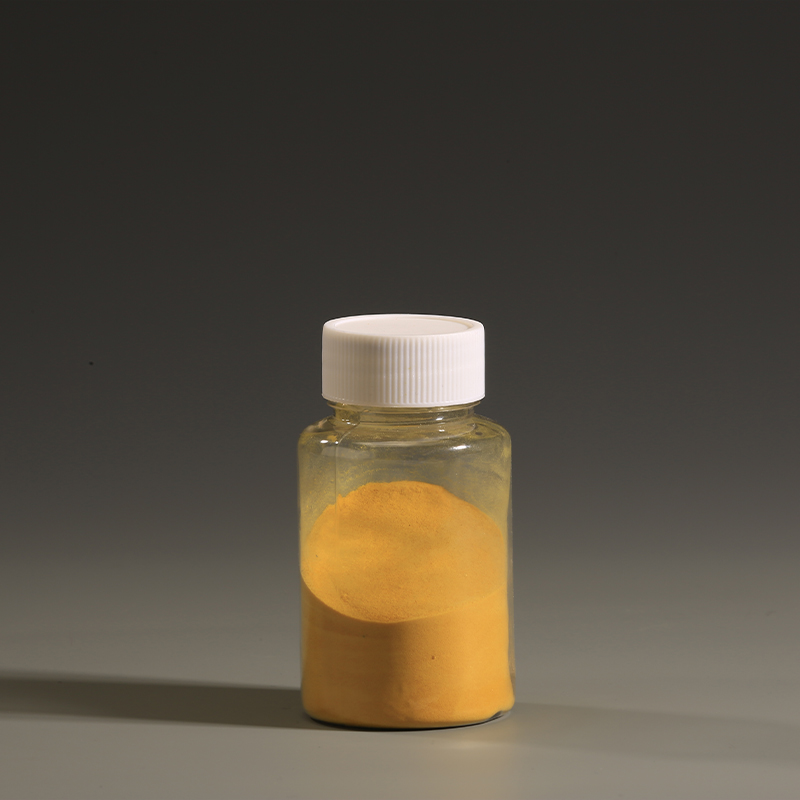

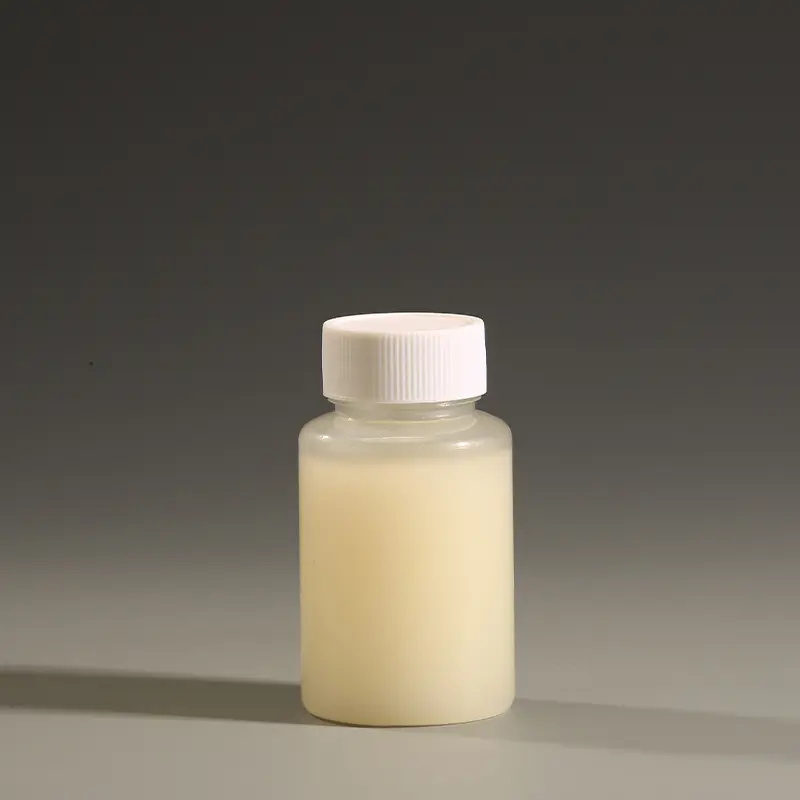

Polyamines represent a class of organic compounds characterized by the presence of multiple amino groups. These compounds, which are typically colorless, thick solution at near neutral pH levels. By adding different amines or polyamines during production, polyamine products with different molecular weights and degrees of branching can be obtained to adapt to different water treatment fields.

Therefore, the applications of polyamines span various industries, including water clarification, oil-water separation, color removal, waste treatment, and latex coagulation in rubber plants. These compounds also find utility in the coating and paper industry, as well as in diverse applications such as meat processing waste treatment, such as in chicken plant waste. Polyamines are available in multiple grades, with solid concentrations ranging from 50 to 60%.

Polyamines excel in coagulating colloidal dispersions, particularly in deposit control applications concerning pulp, stock, wires, or felts. They effectively remove organics and color from recirculating or effluent streams in pulp and paper mills. However, selecting the most cost-effective polyamine product necessitates a performance evaluation tailored to the specific feed or stream intended for treatment. Polyamines can be administered either neat or diluted in-line at the point of treatment.

Dosage requirements for polyamines depend on the severity of the issue at hand. For deposit control in pulp or stock, the dosage typically ranges from 0.25 to 2.5 kilograms of polyamine per ton of pulp or stock (dry basis). When addressing deposit issues on the forming fabric, the recommended dosage ranges from 0.10 to 1.0 milliliters per minute per foot of fabric width.

Proper storage and handling of polyamines are paramount to maintain their efficacy. Polyamines should be stored within the temperature range of 10–32°C. Short-term exposure to temperatures outside this range usually does not harm the product. If frozen, polyamines should be warmed to 26–37°C and thoroughly mixed before use. The shelf life of polyamines typically extends to 12 months.

In practical applications, the combination of Polyamine Flocculants with PAC (polyaluminum chloride) has demonstrated enhanced turbidity removal efficiency in water treatment processes. The PAC/polyamine combination effectively reduces PAC dosage, lowers residual aluminum ion concentration in treated water, and improves turbidity removal.

During storage, polyamines should be kept in their original vented containers, away from heat, direct sunlight. For detailed handling instructions and safety precautions, users should refer to the product label and Safety Data Sheet (SDS).

We are the professional supplier of polyamines for industrial treatment. Polyamine for sale in our company can work greatly for a long time! Get in touch with us! ( Email: sales@yuncangchemical.com )

Post time: Nov-04-2024