In the realm of industrial water treatment, the quest for efficient and effective solutions is paramount. Industrial processes often generate large volumes of wastewater containing suspended solids, organic matter, and other pollutants. Efficient water treatment is crucial not only for regulatory compliance but also for sustainable operations. Poly aluminum chloride ( PAC ) plays a critical role in this process by facilitating coagulation and flocculation, which are essential steps in separating impurities from water.

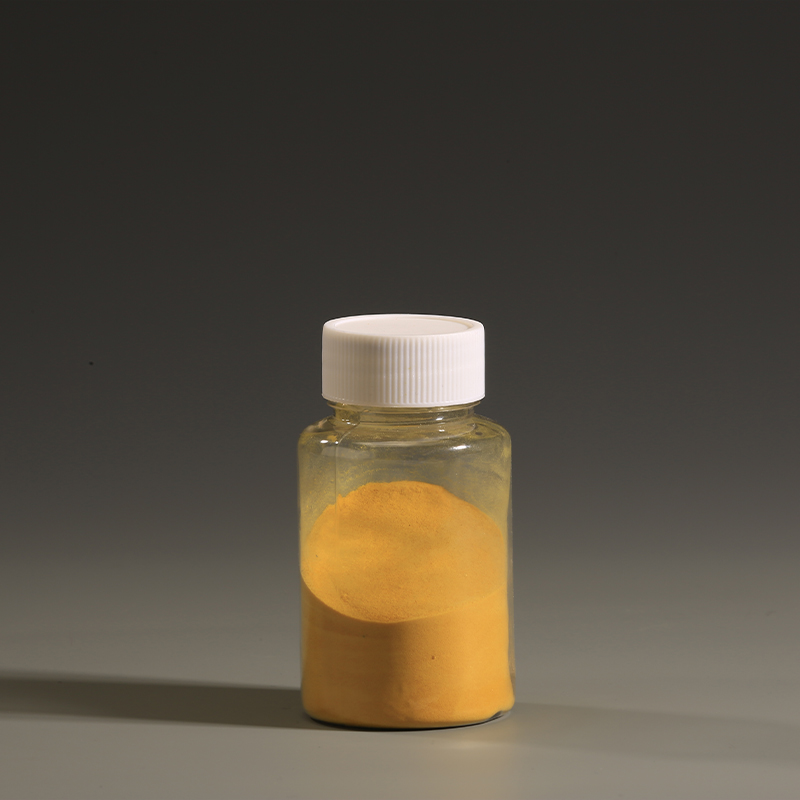

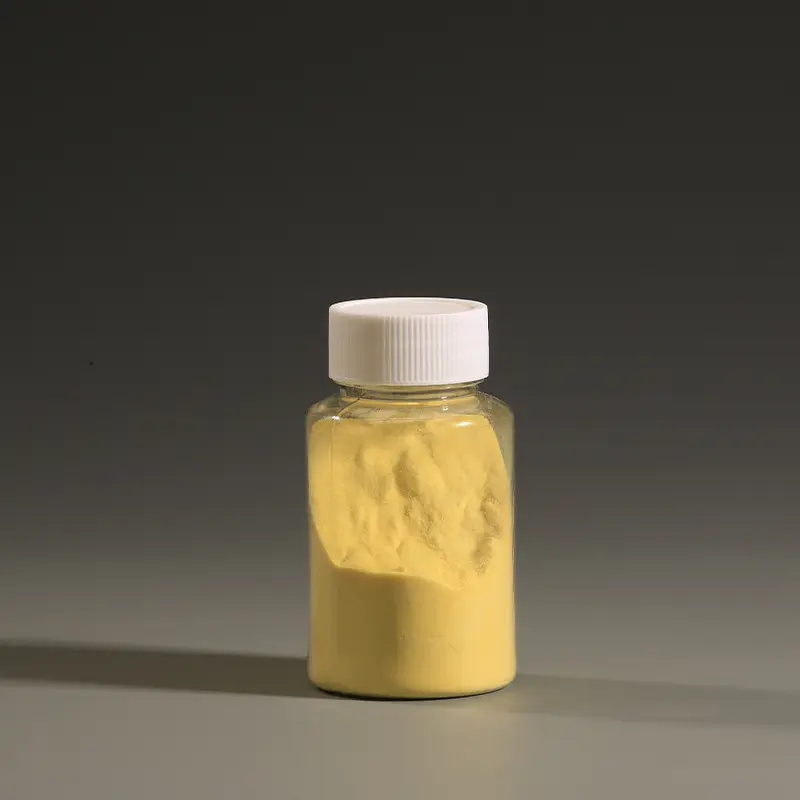

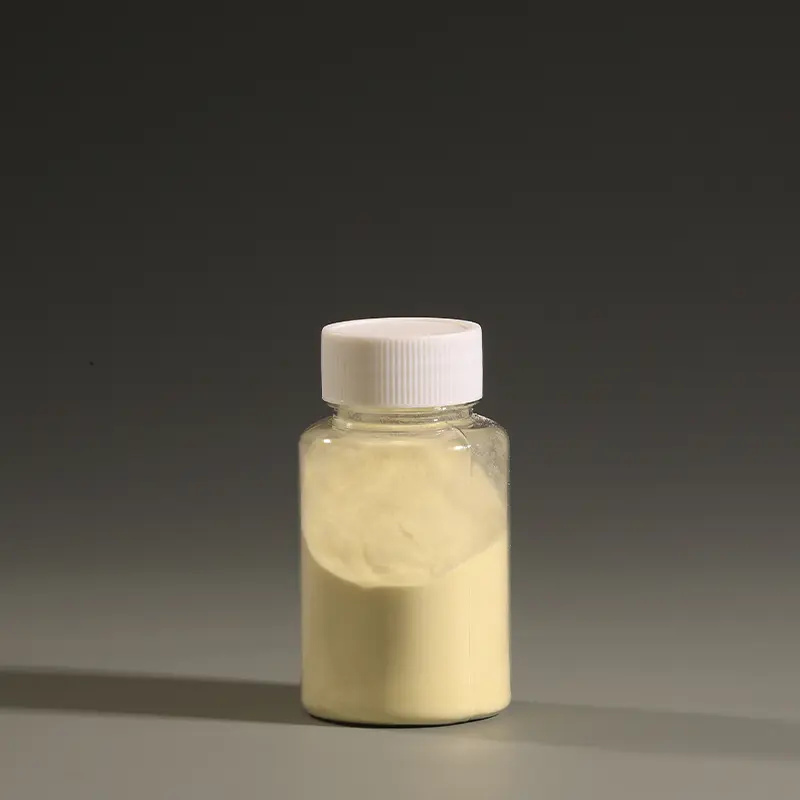

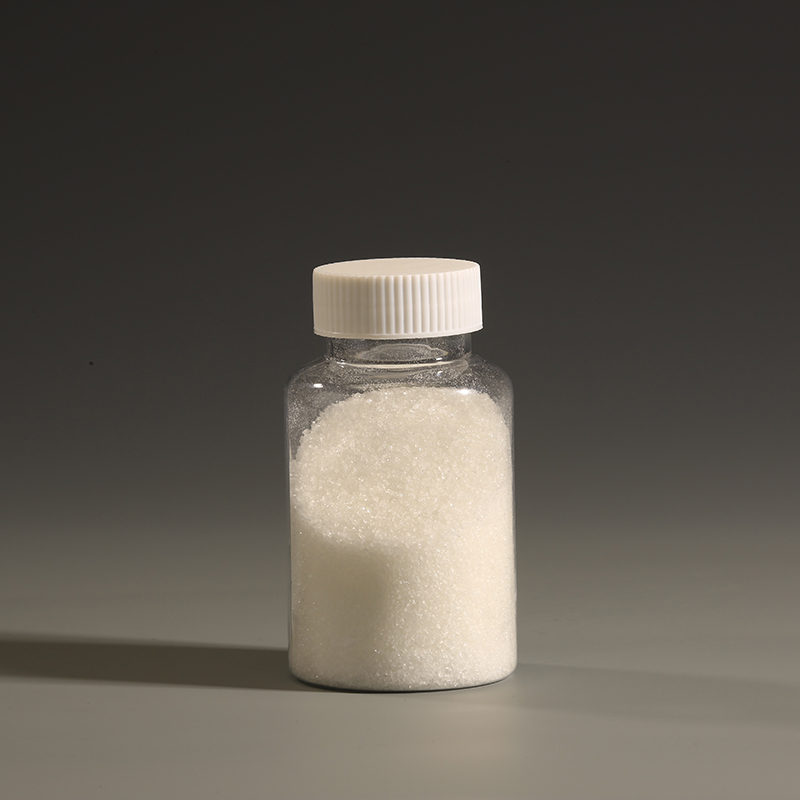

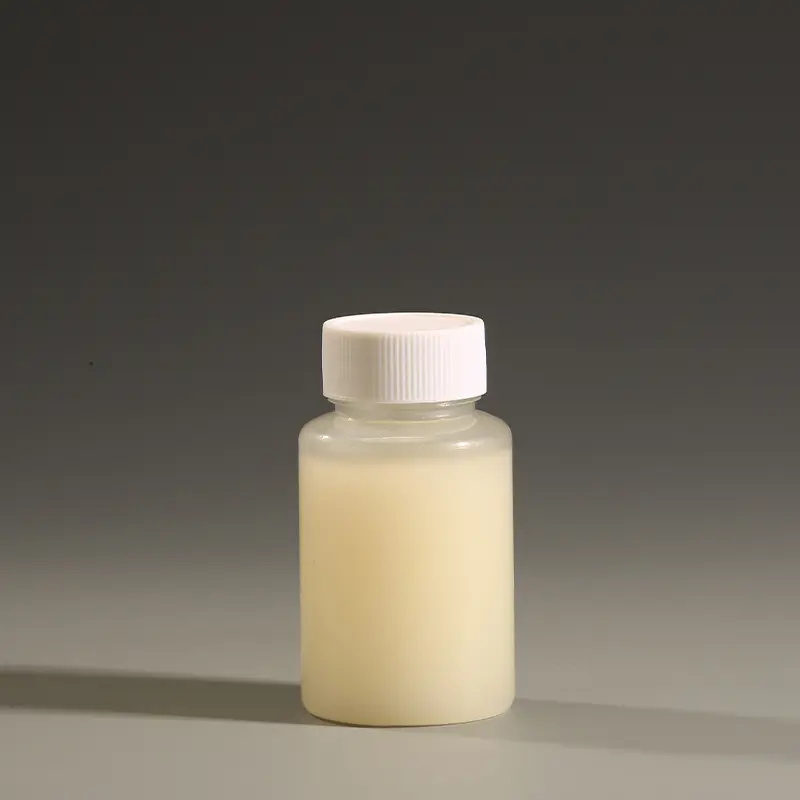

Poly aluminum chloride is a versatile water treatment chemical that functions primarily as a coagulant. Coagulants facilitate the destabilization of colloidal particles in water, allowing them to agglomerate into larger, heavier flocs that can be easily removed through sedimentation or filtration. The unique structure of PAC, characterized by a complex network of aluminum oxyhydroxide polymers, enables it to form larger and denser flocs compared to conventional coagulants such as aluminum sulfate.

Key Benefits of Using PAC in Industrial Water Treatment

Enhanced Coagulation and Flocculation

PAC exhibits superior coagulating properties compared to traditional coagulants like aluminum sulfate. Its polymeric structure allows for the rapid aggregation of fine particles, forming larger and denser flocs. This leads to more effective sedimentation and filtration, resulting in clearer water.

Wide pH Range Effectiveness

One of the significant advantages of PAC is its ability to perform efficiently over a wide pH range (5.0 to 9.0). This makes it suitable for treating different types of industrial wastewater without requiring extensive pH adjustment, saving both time and operational costs.

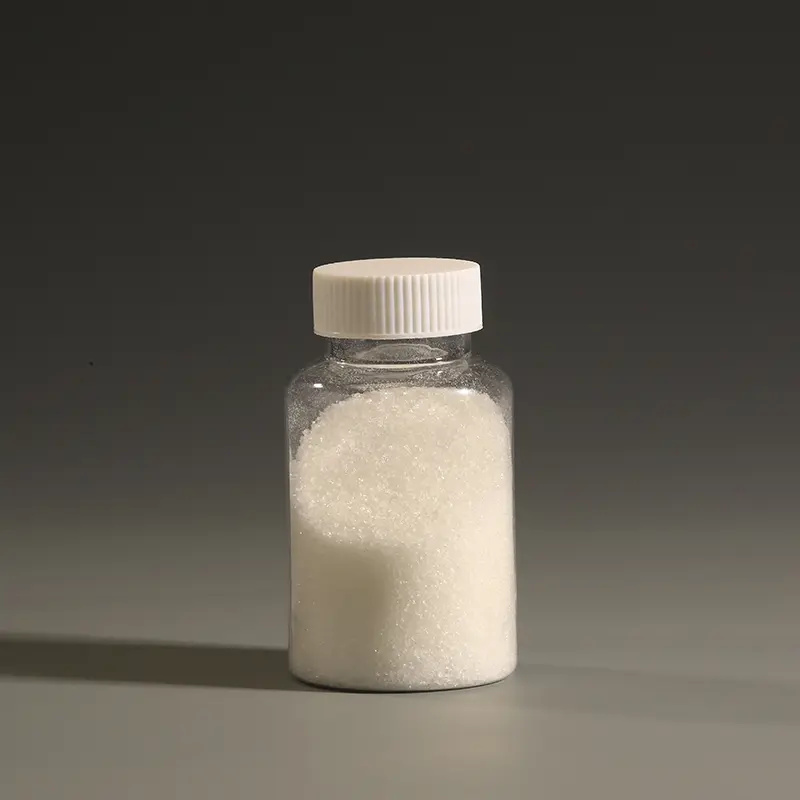

Reduced Sludge Volume

PAC generates less sludge compared to other coagulants, as it requires lower dosages and fewer chemical aids to achieve the desired results. This not only minimizes sludge handling and disposal costs but also reduces the environmental footprint of the treatment process.

Improved Filtration Efficiency

By producing well-structured flocs, PAC enhances the performance of downstream filtration systems. Cleaner water exiting the filtration stage extends the lifespan of filters and reduces maintenance requirements.

Lower Chemical Consumption

The high efficiency of PAC means that less chemical is needed to achieve optimal results. This translates into cost savings and a reduction in the potential environmental impact of residual chemicals in treated water.

Applications of PAC in Industrial Water Treatment

PAC is used across a variety of industries, including:

Textile Industry: Removing dyes and organic impurities from wastewater.

Paper Manufacturing: Enhancing clarity and color removal in process water.

Oil & Gas: Treating produced water and refining effluents.

Food and Beverage: Ensuring compliance with stringent discharge standards.

As industries strive to adopt greener practices, PAC emerges as a sustainable option. Its efficiency at lower dosages, reduced sludge production, and ability to integrate seamlessly with existing treatment systems align with the goals of reducing resource consumption and minimizing waste.

By incorporating PAC into water treatment processes, industries can achieve cleaner effluents, comply with environmental regulations, and contribute to sustainable water management practices. For industries looking to optimize their water treatment systems, PAC offers a reliable and proven solution to meet the demands of modern water purification challenges.

Post time: Dec-30-2024