Flocculation is the process by which negatively charged suspended particles present in a stable suspension in water are destabilized. This is achieved by adding a positively charged coagulant. The positive charge in the coagulant neutralizes the negative charge present in the water (i.e. destabilizes it). Once the particles are destabilized or neutralized, the flocculation process occurs. The destabilized particles combine into larger and larger particles until they are heavy enough to settle out by sedimentation or large enough to trap air bubbles and float.

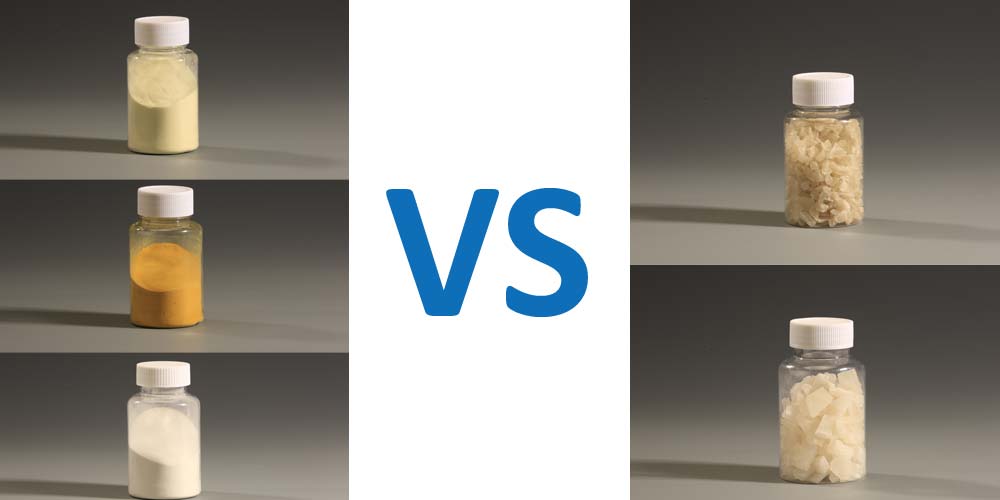

Today we will take a closer look at the flocculation properties of two common flocculants: poly aluminium chloride and aluminum sulfate.

Aluminum Sulfate: Aluminum Sulfate is acidic in nature. The working principle of aluminum sulfate is as follows: aluminum sulfate produces aluminum hydroxide, Al(0H)3. Aluminum hydroxides have a limited pH range, above which they will not effectively hydrolysis or , hydrolyzated aluminum hydroxides settled quickly at high pH (i.e. pH above 8.5), so the operating pH must be carefully controlled to keep it in the range of 5.8-8.5. the alkalinity in the water must be sufficient during the flocculation process to ensure that the insoluble hydroxide is fully formed and precipitated. Removes color and colloidal materials through the combination of adsorption and hydrolysis on/into metal hydroxides. Therefore, the operating pH window of aluminum sulfate is strictly 5.8-8.5, so it is very important to ensure good pH control throughout the process when using aluminum sulfate.

Polyaluminum chloride (PAC) is one of the most effective water treatment chemicals in use today. It is widely used in drinking water and wastewater treatment because of its high coagulation efficiency and the widest range of pH and temperature applications compared to other water treatment chemicals. PAC is available in several different grades with alumina concentrations ranging from 28% to 30%. Alumina concentration is not the only consideration when choosing which grade of PAC to use.

PAC can be considered as a pre-hydrolysis coagulant. The pre-hydrolysis aluminum clusters have a very high positive charge density, which makes PAC more cationic than alum.making it a stronger destabilizer for negatively charged suspended impurities in the water.

PAC has the following advantages over aluminum sulfate

1. It works at much lower concentrations. As a rule of thumb, the PAC dose is about one-third of the dose required for alum.

2. It leaves less residual aluminum in the treated water

3. It produces less sludge

4. It works over a wide pH range

There are many types of flocculants, and this article only introduces two of them. When choosing a coagulant, you should consider the water quality you are treating and your own cost budget. I hope you have a good water treatment experience. As a water treatment chemical supplier with 28 years of experience. I am happy to solve all your problems (about water treatment chemicals).

Post time: Jul-23-2024