Industrial Water Treatment processes and Chemical Applications

Background

With the rapid development of industrialization, the importance of water treatment in various industrial production is becoming increasingly apparent. Industrial water treatment is not only an important link to ensure the smooth progress of the process, but also a key measure to meet environmental regulations and sustainable development requirements.

Water Treatment Type

| Water treatment type | Main purpose | Main treatment objects | Main processes. |

| Raw water pretreatment | Meet the requirements of domestic or industrial water | Natural water source water | Filtration, sedimentation, coagulation. |

| Process water treatment | Meet specific process requirements | Industrial process water | Softening, desalination, deoxygenation. |

| Circulating cooling water treatment | Ensure the normal operation of equipment | Circulating cooling water | Dosing treatment. |

| Wastewater treatment | Protect the environment | Industrial wastewater | Physical, chemical, biological treatment. |

| Recycled water treatment | Reduce fresh water consumption | Used water | Similar to wastewater treatment. |

Commonly used Water Treatment Chemicals

| Category | Commonly used chemicals | Function |

| Flocculating agent | PAC, PAM, PDADMAC, polyamines, aluminum sulfate, etc. | Remove suspended solids and organic matter |

| Disinfectants | such as TCCA, SDIC, ozone, chlorine dioxide, Calcium Hypochlorite, etc | Kills microorganisms in water (such as bacteria, viruses, fungi and protozoa) |

| pH adjuster | Aminosulfonic acid, NaOH, lime, sulfuric acid, etc. | Regulate water pH |

| Metal ion removers | EDTA,Ion exchange resin | Remove heavy metal ions (such as iron, copper, lead, cadmium, mercury, nickel, etc.) and other harmful metal ions in water |

| Scale inhibitor | Organophosphates, organophosphorus carboxylic acids | Prevent scale formation by calcium and magnesium ions. Also has a certain effect of removing metal ions |

| Deoxidizer | Sodium sulfite, hydrazine, etc. | Remove dissolved oxygen to prevent oxygen corrosion |

| Cleaning agent | Citric acid, sulfuric acid, aminosulfonic acid | Remove scale and impurities |

| Oxidants | ozone, persulfate, hydrogen chloride, hydrogen peroxide, etc. | Disinfection, removal of pollutants and improvement of water quality, etc. |

| Softeners | such as lime and sodium carbonate. | Removes hardness ions (calcium, magnesium ions) and reduces the risk of scale formation |

| Defoamers / Antifoam | Suppress or eliminate foam | |

| Removal | Calcium Hypochlorite | remove NH₃-N from wastewater to make it meet discharge standards |

Water Treatment Chemicals We Can Supply:

Industrial water treatment refers to the process of treating industrial water and its discharge water through physical, chemical, biological and other methods. Industrial water treatment is an indispensable part of industrial production, and its importance is reflected in the following aspects:

1.1 Ensure product quality

Remove impurities in water such as metal ions, suspended solids, etc. to meet production needs and ensure product quality.

Inhibit corrosion: Dissolved oxygen, carbon dioxide, etc. in water can cause corrosion of metal equipment and shorten the life of the equipment.

Control microorganisms: Bacteria, algae and other microorganisms in water can cause product contamination, affecting product quality and health safety.

1.2 Improve production efficiency

Reduce downtime: Regular water treatment can effectively prevent equipment scaling and corrosion, reduce the frequency of equipment maintenance and replacement, and thus improve production efficiency.

Optimize process conditions: Through water treatment, water quality that meets process requirements can be obtained to ensure the stability of the production process.

1.3 Reduce production costs

Save energy: Through water treatment, equipment energy consumption can be reduced and production costs can be saved.

Prevent scaling: Hardness ions such as calcium and magnesium ions in water will form scale, adhere to the surface of the equipment, reduce heat conduction efficiency.

Extend equipment life: Reduce equipment corrosion and scaling, extend equipment service life, and reduce equipment depreciation costs.

Reduce material consumption: Through water treatment, the waste of biocides can be reduced and production costs can be reduced.

Reduce raw materials consumption: Through water treatment, the remaining raw materials in the waste liquid can be recovered and put back into production, thus reducing the waste of raw materials and lowering production costs.

1.4 Protect the environment

Reduce pollutant emissions: After industrial wastewater is treated, the concentration of pollutant emissions can be reduced and the water environment can be protected.

Realize the recycling of water resources: Through water treatment, industrial water can be recycled and dependence on fresh water resources can be reduced.

1.5 Comply with environmental regulations

Meet emission standards: Industrial wastewater must meet national and local emission standards, and water treatment is an important means to achieve this goal.

In summary, industrial water treatment is not only related to product quality and production efficiency, but also to the economic benefits and environmental protection of enterprises. Through scientific and reasonable water treatment, the optimal utilization of water resources can be achieved and the sustainable development of industry can be promoted.

Industrial water treatment covers a wide range of fields, including power, chemical, pharmaceutical, metallurgy, food and beverage industries, etc. Its treatment process is usually customized according to water quality requirements and discharge standards.

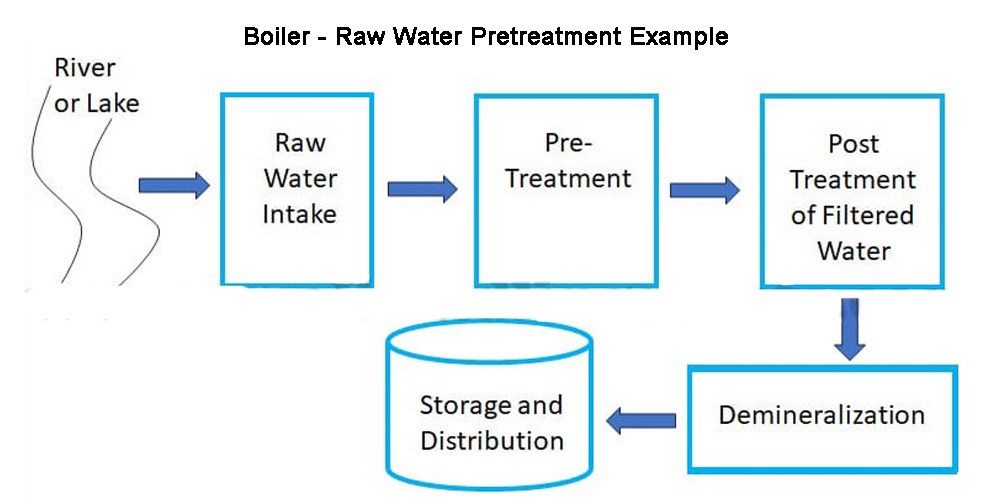

2.1 Chemicals and Principles of Influent Treatment (Raw Water Pretreatment)

Raw water pretreatment in industrial water treatment mainly includes primary filtration, coagulation, flocculation, sedimentation, flotation, disinfection, pH adjustment, metal ion removal and final filtration. Commonly used chemicals include:

Coagulants and flocculants: such as PAC, PAM, PDADMAC, polyamines, aluminum sulfate, etc.

Softeners: such as lime and sodium carbonate.

Disinfectants: such as TCCA, SDIC, Calcium Hypochlorite, ozone, chlorine dioxide, etc.

pH adjusters: such as aminosulfonic acid, sodium hydroxide, lime, sulfuric acid, etc.

Metal ion removersEDTA, Ion exchange resin etc.,

scale inhibitor: organophosphates, organophosphorus carboxylic acids, etc.

Adsorbents: such as activated carbon, activated alumina, etc.

The combination and use of these chemicals can help industrial water treatment effectively remove suspended matter, organic pollutants, metal ions and microorganisms in water, ensure that water quality meets production needs, and reduce the burden of subsequent treatment.

2.2 Chemicals and Principles of Process Water Treatment

Process water treatment in industrial water treatment mainly includes pretreatment, softening, deoxidation, iron and manganese removal, desalination, sterilization and disinfection. Each step requires different chemicals to optimize water quality and ensure the normal operation of various industrial equipment. Common chemicals include:

|

Coagulants and flocculants: |

such as PAC, PAM, PDADMAC, polyamines, aluminum sulfate, etc. |

|

Softeners: |

such as lime and sodium carbonate. |

|

Disinfectants: |

such as TCCA, SDIC, Calcium Hypochlorite, ozone, chlorine dioxide, etc. |

|

pH adjusters: |

such as aminosulfonic acid, sodium hydroxide, lime, sulfuric acid, etc. |

|

Metal ion removers: |

EDTA, Ion exchange resin |

|

Scale inhibitor: |

organophosphates, organophosphorus carboxylic acids, etc. |

|

Adsorbents: |

such as activated carbon, activated alumina, etc. |

These chemicals can meet the different needs of process water through different water treatment process combinations, ensure that water quality meets production standards, reduce the risk of equipment damage, and improve production efficiency.

2.3 Chemicals and Principles of Circulating Cooling Water Treatment

Circulating cooling water treatment is a very important part of industrial water treatment, especially in most industrial facilities (such as chemical plants, power plants, steel plants, etc.), where cooling water systems are widely used for cooling equipment and processes. Circulating cooling water systems are susceptible to scaling, corrosion, microbial growth and other problems due to their large water volume and frequent circulation. Therefore, effective water treatment methods must be used to control these problems and ensure the stable operation of the system.

Circulating cooling water treatment aims to prevent scaling, corrosion and biological contamination in the system and ensure cooling efficiency. Monitor the main parameters in cooling water (such as pH, hardness, turbidity, dissolved oxygen, microorganisms, etc.) and analyze water quality problems for targeted treatment.

|

Coagulants and flocculants: |

such as PAC, PAM, PDADMAC, polyamines, aluminum sulfate, etc. |

|

Softeners: |

such as lime and sodium carbonate. |

|

Disinfectants: |

such as TCCA, SDIC, Calcium Hypochlorite, ozone, chlorine dioxide, etc. |

|

pH adjusters: |

such as aminosulfonic acid, sodium hydroxide, lime, sulfuric acid, etc. |

|

Metal ion removers: |

EDTA, Ion exchange resin |

|

Scale inhibitor: |

organophosphates, organophosphorus carboxylic acids, etc. |

|

Adsorbents: |

such as activated carbon, activated alumina, etc. |

These chemicals and treatment methods help prevent scaling, corrosion, and microbial contamination, ensure the long-term stable operation of the cooling water system, reduce equipment damage and energy consumption, and improve system efficiency.

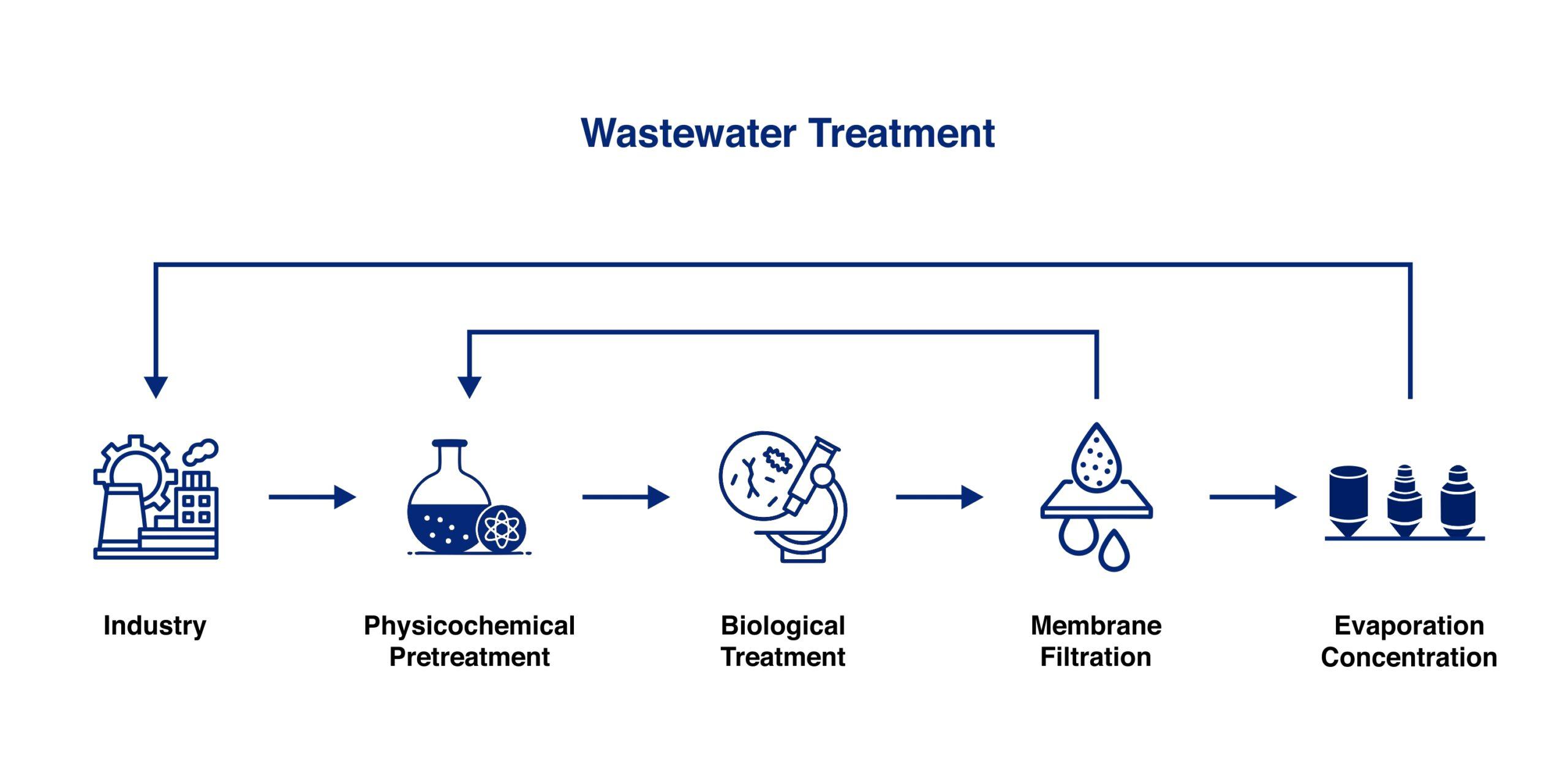

2.4 Chemicals and Principles of Wastewater Treatment

The process of industrial wastewater treatment can be divided into multiple stages according to the characteristics of wastewater and treatment objectives, mainly including pretreatment, acid-base neutralization, removal of organic matter and suspended solids, intermediate and advanced treatment, disinfection and sterilization, sludge treatment and recycled water treatment. Each link requires different chemicals to work together to ensure the efficiency and thoroughness of the wastewater treatment process.

Industrial wastewater treatment is divided into three main methods: physical, chemical and biological, in order to meet emission standards and reduce environmental pollution.

Physical method: sedimentation, filtration, flotation, etc.

Chemical method: neutralization, redox, chemical precipitation.

Biological method: activated sludge method, membrane bioreactor (MBR), etc.

Common chemicals include:

|

Coagulants and flocculants: |

such as PAC, PAM, PDADMAC, polyamines, aluminum sulfate, etc. |

|

Softeners: |

such as lime and sodium carbonate. |

|

Disinfectants: |

such as TCCA, SDIC, Calcium Hypochlorite, ozone, chlorine dioxide, etc. |

|

pH adjusters: |

such as aminosulfonic acid, sodium hydroxide, lime, sulfuric acid, etc. |

|

Metal ion removers: |

EDTA, Ion exchange resin |

|

Scale inhibitor: |

organophosphates, organophosphorus carboxylic acids, etc. |

|

Adsorbents: |

such as activated carbon, activated alumina, etc. |

Through the effective application of these chemicals, industrial wastewater can be treated and discharged in compliance with standards, and even reused, helping to reduce environmental pollution and water resource consumption.

2.5 Chemicals and Principles of Recycled Water Treatment

Recycled water treatment refers to a water resource management method that reuses industrial wastewater after treatment. With the increasing shortage of water resources, many industrial fields have adopted recycled water treatment measures, which not only saves water resources, but also reduces the cost of treatment and discharge. The key to recycled water treatment is to remove pollutants in wastewater so that the water quality meets the requirements for reuse, which requires high processing accuracy and technology.

The process of recycled water treatment mainly includes the following key steps:

Pretreatment: remove large particles of impurities and grease, using PAC, PAM, etc.

pH adjustment: adjust pH, commonly used chemicals include sodium hydroxide, sulfuric acid, calcium hydroxide, etc.

Biological treatment: remove organic matter, support microbial degradation, use ammonium chloride, sodium dihydrogen phosphate, etc.

Chemical treatment: oxidative removal of organic matter and heavy metals, commonly used ozone, persulfate, sodium sulfide, etc.

Membrane separation: use reverse osmosis, nanofiltration, and ultrafiltration technology to remove dissolved substances and ensure water quality.

Disinfection: remove microorganisms, use chlorine, ozone, calcium hypochlorite, etc.

Monitoring and adjustment: Ensure that the reused water meets the standards and use regulators and monitoring equipment for adjustments.

Defoamers: They suppress or eliminate foam by reducing the surface tension of the liquid and destroying the stability of the foam. ( Application scenarios of defoamers: biological treatment systems, chemical wastewater treatment, pharmaceutical wastewater treatment, food wastewater treatment, papermaking wastewater treatment, etc. )

Calcium hypochlorite: They remove pollutants such as ammonia nitrogen

The application of these processes and chemicals ensures that the quality of the treated wastewater meets the reuse standards, allowing it to be effectively used in industrial production.

Industrial water treatment is an important part of modern industrial production. Its process and chemical selection need to be optimized according to specific process requirements. The rational application of chemicals can not only improve the treatment effect, but also reduce costs and reduce the impact on the environment. In the future, with the advancement of technology and the improvement of environmental protection requirements, industrial water treatment will develop in a more intelligent and green direction.