Factory wholesale Aluminum Sulfate With Low Fe Content - Flocculant – Polyacrylamide (PAM) – Yuncang

Factory wholesale Aluminum Sulfate With Low Fe Content - Flocculant – Polyacrylamide (PAM) – Yuncang Detail:

Product Introduction

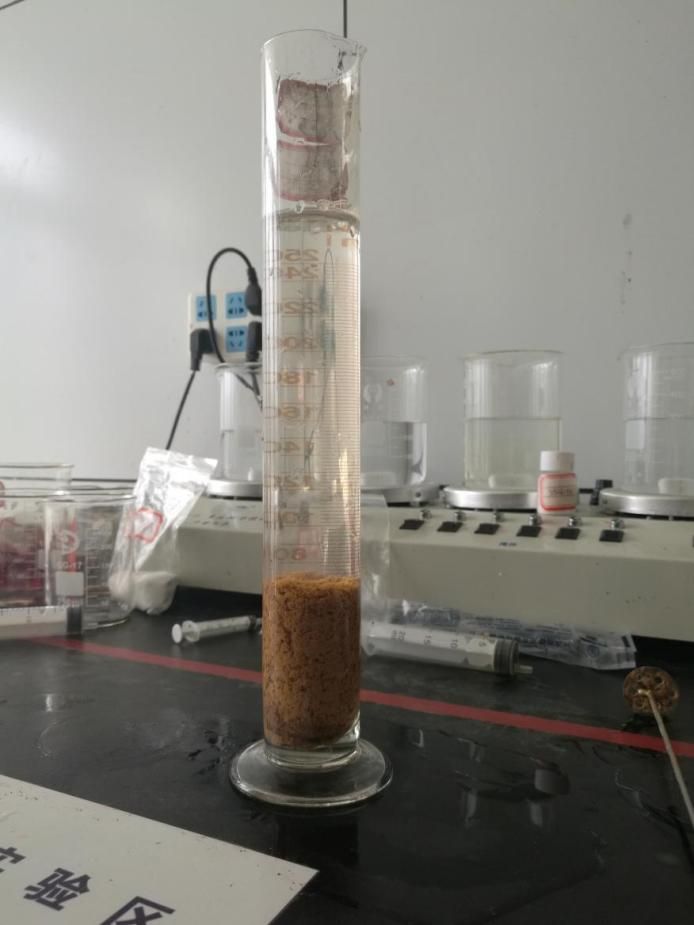

Polyacrylamide (PAM) powder is a kind of acrylic polymer and polyelectrolyte, applied as flocculant, coagulant, dispersant in many fields.

Polyacrylamide (PAM) emulsion is high efficiency and instant liquid flocculant with different molecular weight and different charge density. The main application field.

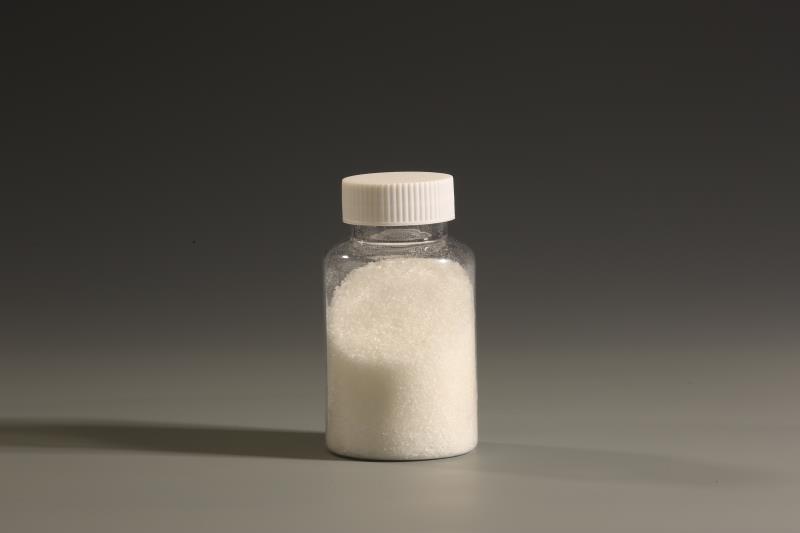

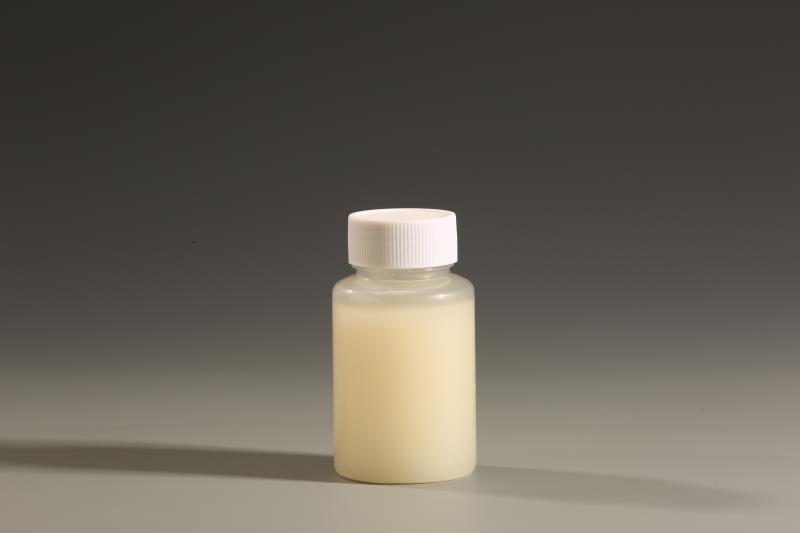

Product Display

Technical Specifications

Polyacrylamide (PAM) powder

| Type | Cationic PAM (CPAM) | Anionic PAM(APAM) | Nonionic PAM(NPAM) |

| Appearance | White powder | White powder | White powder |

| Solid content, % | 88 MIN | 88 MIN | 88 MIN |

| pH Value | 3 – 8 | 5 – 8 | 5 – 8 |

| Molecular Weight, x106 | 6 – 15 | 5 – 26 | 3 – 12 |

| Degree of Ion, % | Low, Medium, High |

||

| Dissolving Time, min | 60 – 120 | ||

Polyacrylamide (PAM) emulsion:

| Type | Cationic PAM (CPAM) | Anionic PAM (APAM) | Nonionic PAM (NPAM) |

| Solid Content, % | 35 – 50 | 30 – 50 | 35 – 50 |

| pH | 4 – 8 | 5 – 8 | 5 – 8 |

| Viscosity, mPa.s | 3 – 6 | 3 – 9 | 3 – 6 |

| Dissolving time, min | 5 – 10 | 5 – 10 | 5 – 10 |

Application

1. Municipal Water Treatment.

2. Industrial Wastewater Treatment.

3. Paper-making Industry: Paper Retention agent, Paper Strength agent, Paper dispersant agent, Anionic garbage capture agent, White water treatment.

4. Mining Processing: Polyacrylamide is widely used in the mineral processing industry, especially in the process of sedimentation and separation. Our products range offers the high molecular weight and high charge to satisfy the clients’ need.

5. Other Industrial Process: Food processing, Sugar & Juice, Textile & Dying etc.

6. Enhanced Oil Recovery Chemicals: Profile control and water shutoff, Drilling mud, Tertiary oil recovery (EOR).

Package And Storage

● Recommended concentration for feed: 0.025-0.1% (max)

● Storage temperature: 0-35°C

● Storage periods for solid: 24 months.

Product detail pictures:

Related Product Guide:

Often customer-oriented, and it's our ultimate target to become not only probably the most reputable, trustable and honest provider, but also the partner for our customers for Factory wholesale Aluminum Sulfate With Low Fe Content - Flocculant – Polyacrylamide (PAM) – Yuncang , The product will supply to all over the world, such as: venezuela, Los Angeles, Lisbon, With the superior and exceptional service, we are well developed along with our customers. Expertise and know-how ensure that we are always enjoying the trust from our customers in our business activities. "Quality", "honesty" and "service" is our principle. Our loyalty and commitments remain respectfully at your service. Contact Us Today For further information, contact us now.

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.